Here is SUMITOMO's new cone shape fender, Hyper Omega-Type. By Optimizing the shape of the former PIVOT fender, SUMITOMO's advanced technology has succeeded in improving the performance of this product to the highest level of its kind in the industry. Are you ready to take the ultimate step into the future?

Merits of Hyper Omega-Type

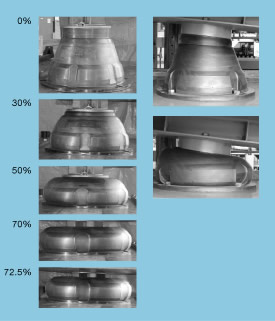

The belt-shaped projection is set up on the outer surface. This design strengthens the base section of the fender against deflection, and provides increased reaction load and therefore increased energy absorption capacity at the earliest stage of compression.

The belt-shaped projection can also be set up on the inner surface. This design reduces the scrub of rubber body, and in return, helps smooth deforming. The reaction load level can be maintained to a high level of deflection.

By affixing the mounting to the steel frame, and the level created on the upper surface of fender, the compressibility (energy absorption capacity) is increased.

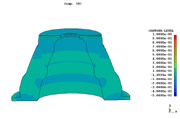

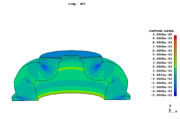

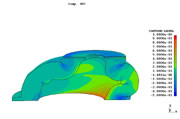

FEM

| Rubber compound | X155 | X150 | X140 | X120 | ||||

| Deflection | 70.0% | 70.0% | 70.0% | 70.0% | ||||

|

R (kN) |

E (kN-m) |

R (kN) |

E (kN-m) |

R (kN) |

E (kN-m) |

R (kN) |

E (kN-m) |

| 400H | 194 | 43.4 | 188 | 42.0 | 176 | 39.2 | 151 | 33.6 |

| 600H | 438 | 147 | 423 | 142 | 395 | 132 | 339 | 113 |

| 800H | 778 | 347 | 753 | 336 | 703 | 314 | 602 | 269 |

| 900H | 984 | 494 | 953 | 479 | 889 | 447 | 762 | 383 |

| 1000H | 1215 | 678 | 1176 | 656 | 1098 | 613 | 941 | 525 |

| 1150H | 1607 | 1032 | 1555 | 998 | 1452 | 932 | 1244 | 799 |

| 1300H | 2054 | 1490 | 1988 | 1442 | 1855 | 1346 | 1590 | 1154 |

| 1450H | 2555 | 2068 | 2473 | 2001 | 2308 | 1868 | 1978 | 1601 |

| 1600H | 3111 | 2778 | 3011 | 2689 | 2810 | 2510 | 2409 | 2151 |

| 1800H | 3938 | 3956 | 3811 | 3828 | 3557 | 3573 | 3049 | 3063 |

| Rubber compound | X100 | X80 | X60 | |||

| Deflection | 70.0% | 70.0% | 70.0% | |||

|

R kN |

E kN-m |

R kN |

E kN-m |

R kN |

E kN-m |

| 400H | 125 | 28.0 | 104 | 22.2 | 78.8 | 16.2 |

| 600H | 282 | 94.5 | 234 | 75.0 | 177 | 54.7 |

| 800H | 502 | 224 | 417 | 178 | 315 | 130 |

| 900H | 635 | 319 | 527 | 253 | 399 | 185 |

| 1000H | 784 | 438 | 651 | 347 | 492 | 253 |

| 1150H | 1037 | 666 | 861 | 528 | 651 | 385 |

| 1300H | 1325 | 961 | 1100 | 763 | 832 | 557 |

| 1450H | 1649 | 1334 | 1368 | 1059 | 1035 | 772 |

| 1600H | 2007 | 1793 | 1666 | 1422 | 1260 | 1038 |

| 1800H | 2541 | 2552 | 2109 | 2025 | 1595 | 1477 |

R : Reaction Load (kN), E : Energy Absorption (kN-m)

Tolerance : Reaction load = less than +10%, energy absorption = more than -10%

| Rubber Compound | X155 | X150 | X140 | X130 | X120 | X110 | X100 | X90 | X80 | X70 | X60 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Performance Index | 1.55 | 1.50 | 1.40 | 1.30 | 1.20 | 1.10 | 1.00 | 0.90 | 0.80 | 0.70 | 0.60 |

| Hardness | Hard <---------------------------> Soft | ||||||||||

*Special rubber compound can be available developing on design conditions.

*The data are subject to change without notice.

Performance in Angular Compression

| Compression Angle (deg.) |

CR | CE |

| 0 | 1.0 | 1.00 |

| 3 | 1.0 | 1.00 |

| 5 | 1.0 | 1.00 |

| 6 | 1.0 | 1.00 |

| 7 | 1.0 | 1.00 |

| 8 | 1.0 | 0.99 |

| 9 | 1.0 | 0.98 |

| 10 | 1.0 | 0.97 |

| 15 | 1.0 | 0.94 |

| 20 | 1.0 | 0.87 |

●CR : Ratio for Reaction Load

●CE : Ratio for Energy Absorption